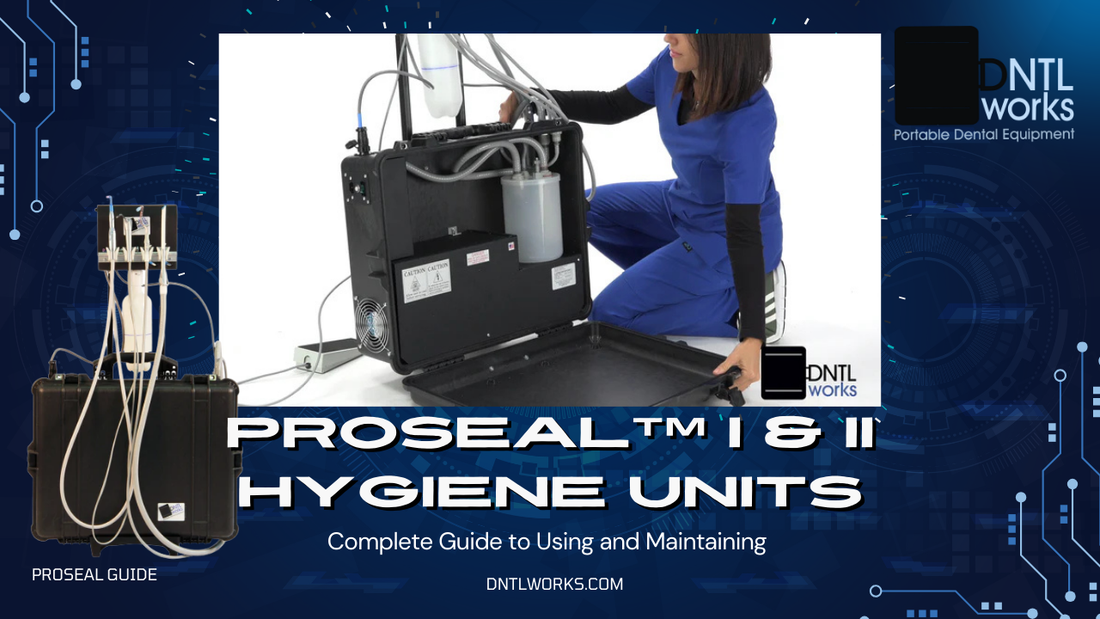

Complete Guide to Using and Maintaining Your ProSeal™ I & II Hygiene Units

Share

Daily Setup and Operation

Morning Setup Protocol

- Fill internal water reservoir with distilled water

- ProSeal I: 1 liter capacity

- ProSeal II: 1.5 liter capacity

- Add water treatment tablet (BluTab or equivalent)

- Prime water lines for 2 minutes

- Test suction systems (both saliva ejector and HVE)

- Verify compressor operation

- Check all connections and seals

Essential Equipment Check

- Air pressure gauge reading (should be 35-45 PSI)

- Water flow rate from all handpiece connections

- Suction power on both evacuation systems

- Filter condition and placement

- Waste container seal integrity

Recommended Cleaning Products

Water Line Treatment

-

Daily Use:

- BluTab Waterline Treatment Tablets

- ICX Tablets by A-dec

- Sterisil Tablets

Suction Line Cleaners

-

Primary Options:

- ProEZ AW Cleaner (Certol)

- Vacusol Ultra (Schultz)

- PureVac SC (Sultan Healthcare)

Surface Disinfectants

-

Approved Products:

- CaviWipes1 (Metrex)

- DisCide ULTRA Disinfecting Spray

- BirexSE Surface Disinfectant

Cleaning Procedures

Between Patients (5-7 minutes)

- Draw vacuum line cleaner through both suction systems

- Use 8oz through HVE

- Use 4oz through saliva ejector

- Wipe all surfaces with approved disinfectant

- Replace barriers on frequently touched surfaces

- Check water level

- Empty waste container if more than 2/3 full

End of Day Protocol (20-25 minutes)

- Run enzymatic cleaner through suction lines

- ProEZ AW: 16oz solution per line

- Contact time: 3 minutes

- Flush with clean water for 2 minutes

- Empty and clean waste container

- Clean or replace suction filters

- Wipe down unit exterior

- Run air through water lines to dry

- Empty water reservoir

Maintenance Schedule

Daily Tasks

- Check water level

- Clean suction filters

- Verify pressure readings

- Test all functions

- Clean external surfaces

Weekly Tasks

- Deep clean suction system

- Inspect all O-rings and seals

- Check compressor operation

- Clean water filters

- Lubricate O-rings if needed

Monthly Tasks

- Replace water filters

- Deep clean water reservoir

- Check electrical connections

- Calibrate pressure settings

- Test safety valves

Troubleshooting Guide

Low Suction Power

- Check waste container level

- Inspect and clean filters

- Verify hose connections

- Test both suction systems separately

Quick Fix: Keep spare filters and suction tips ready

Compressor Issues

- Check power supply

- Verify pressure gauge reading

- Listen for unusual sounds

- Test air delivery to all ports

Quick Fix: Use backup compressed air source if available

Water Flow Problems

- Check reservoir level

- Inspect for kinked lines

- Clean inline filters

- Test pump operation

Quick Fix: Keep backup water lines handy

Emergency Kit Contents

- Spare filters (2 sets)

- Extra O-rings

- Backup suction tips

- Basic tool kit

- Spare water lines

- Extra collection canister

- Pressure gauge

- Voltage tester

Supply Inventory Management

Weekly Stock Check

- Barrier products

- Surface disinfectants

- Water treatment tablets

- Suction line cleaners

Monthly Inventory

- Filters

- O-rings

- Cleaning solutions

- Basic supplies

Quarterly Assessment

- Backup parts

- Tool condition

- Emergency supplies

- Documentation needs

Documentation Requirements

Daily Logs

- Cleaning procedures completed

- Patient load

- Maintenance performed

- Supply usage

Monthly Reports

- Equipment performance

- Supply inventory

- Maintenance records

- Issue documentation

Safety Guidelines

Personal Protection

- Always wear appropriate PPE

- Use eye protection when cleaning

- Maintain proper ventilation

- Follow chemical handling protocols

Equipment Protection

- Never exceed pressure limits

- Keep unit level during operation

- Protect from extreme temperatures

- Use only approved cleaning products

Transportation Tips

Pre-Transport Checklist

- Empty all water and waste containers

- Secure all components

- Pack cleaning supplies separately

- Protect from temperature extremes

- Use original case when possible

Setup at New Location

- Allow unit to reach room temperature

- Check for transport damage

- Test all systems before use

- Verify power supply stability

Model-Specific Considerations

ProSeal I

- Smaller water reservoir (1L)

- Compact design for tight spaces

- Lighter weight for easier transport

- More frequent water refills needed

ProSeal II

- Larger water capacity (1.5L)

- Enhanced suction power

- Additional storage space

- Higher weight capacity

Remember: Both models require annual professional servicing to maintain warranty coverage and optimal performance. Keep detailed records of all maintenance and cleaning procedures for compliance and warranty purposes.